MD422 - Center bore measurement

The NUMTEC MD422 measuring machine is a system for the fully automated center bore measurement of the wheel hub in the processing cells. To implement the automation trend toward chaotically fed processing cells in wheel production, the hub borehole measurement in every cell is unavoidable. With the MD422, it can be done.

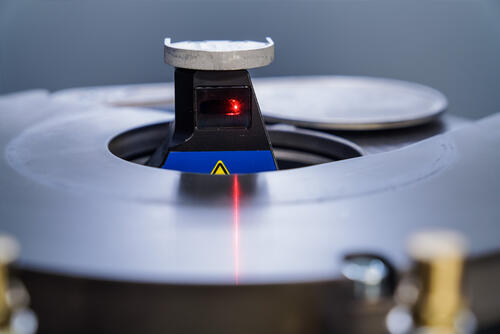

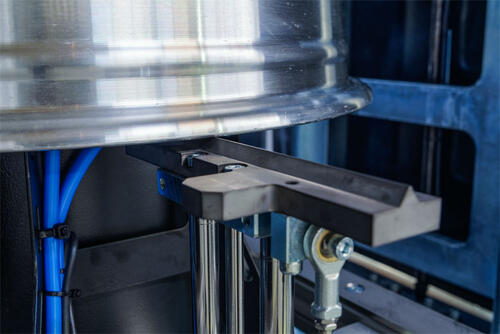

The system is loaded by a robot or via conveyors; after that, the centering and lowering into the measuring position takes place. During the lowering, the A-value is determined, which can be used for the correction of the bolt hole depth. The center bore measurement takes place in a diameter range from 48 to 85 mm with a contactless laser sensor that was specially developed for this application. In order to be able to correct the center bore within the control limits, the measured values are transferred to the CNC processing machine. With an optional positioning system, the valve hole is detected by a camera and positioned for the drilling. Then the wheel is lifted into the removal position and from there, it can be removed by robot or conveyed to the rejection conveyor. With an automatic calibration device, the function of the system is checked at regular intervals using a setting ring. Thanks to the compact design of the machine with an external control cabinet, it can be integrated into existing cells. Standard interfaces are available for connection to the cell control system. A dedicated Ethernet interface is used to gain access to measurement and analysis data. This means that all measured data can also be accessed from the existing network.

Your advantages:

- Laser measurement: The measurement is performed with a contactless laser sensor without mechanical wear.

- Chaotic production: The measuring system can chaotically measure wheels with a hub diameter of 48 to 85 mm -> no retooling time is needed. The center bore range is corrected within the control limits by the calculated correction values.

- Automatic monitoring of the calibration: At regular intervals, the function of the system is checked on an automatic calibration device.

- Fully automatic processing cell: With this complete station, a chaotically fed, fully automated processing cell can be realized.

- Valve hole positioning: Optional camera system for positioning the valve hole for drilling

Contact person

DE

DE EN

EN CN

CN RU

RU