KNORR

The ever-increasing demands on quality and tight tolerances for achieving higher quality assurance in finished steel products have required a growing range of automated quality control technology in the steel production process. KNORR machines inspect your products according to the set standards, and all test results will be recorded.

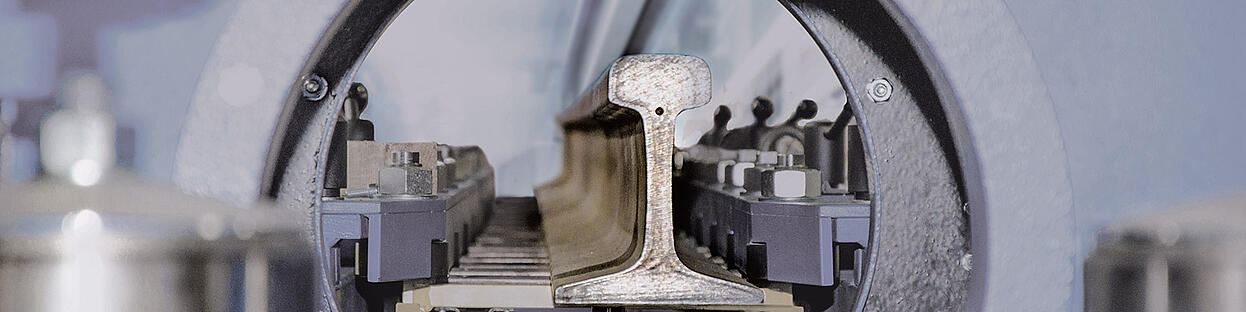

With the brand Knorr, Alpine Metal Tech is a leading provider of flexible, industry-proven, optoelectronic measuring and image processing systems for the contactless, fully automated inspection of the most complex sections, including rails, beams, angles, round bars, flat bars, squares, and tubes. Knorr’s turnkey, nondestructive inspection lines encompass everything from design, engineering, supply, and installation to final commissioning of integrated lines for products such as rails. The lines essentially comprise brushing machines for the removal of loose scales, measurement gauges, straightness measuring units, eddy current testing units for detecting surface defects, and ultrasonic testing units for internal defects.

DE

DE EN

EN CN

CN RU

RU