OIS Optical Inspection System

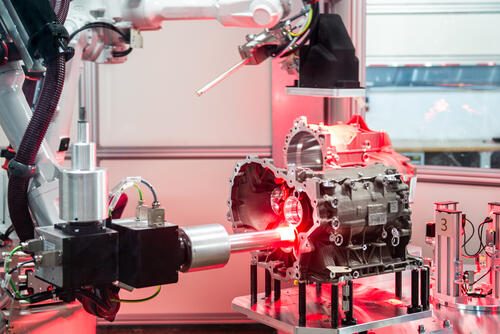

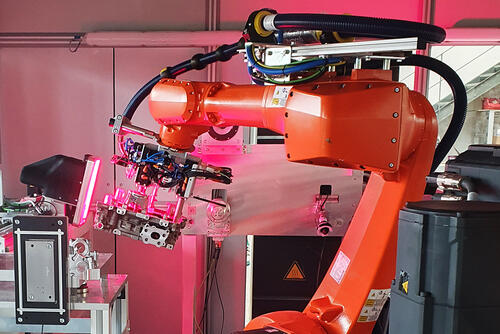

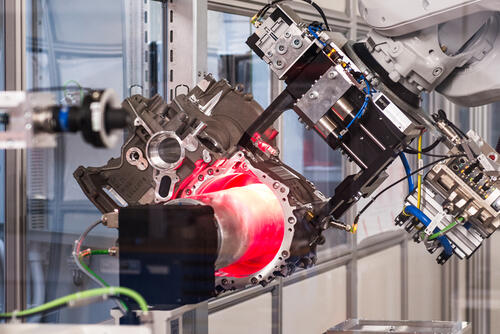

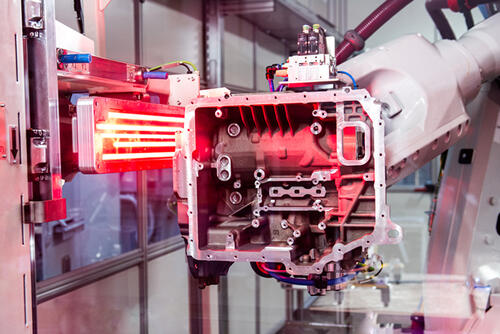

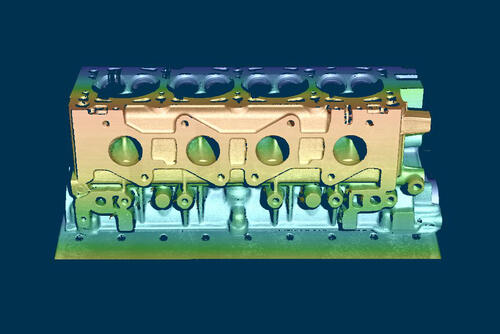

In the case of cast aluminum components, blowholes on functional surfaces can be visible after machining. As a result, the part is scrap or the quality for subsequent processes is not achieved and rework is necessary. To ensure that only high-quality products are delivered, Alpine Metal Tech offers a fully automatic optical inspection cell for 100% control during production.

Workpieces are manufactured with different surface finishes, where also different tolerances are needed; e.g. liquid sealing area (rough surface), solid sealing area (smooth surface), water connections (very fine surface), complex manufactured functional surfaces. The optical test system checks these surfaces for damage, blowholes, dirt and various surface anomalies and records the results. These results can be visualized for the final check at the final test station.

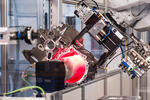

With the help of a combination of different sensor technologies, complex components such as cylinder heads, crankcases or e-housings can be tested. Alpine Metal Tech offers a customer-specific inspection cell adapted to the requirements from a single source.

Your advantages:

- Measurement of different features like bores and plane surfaces possible

- Flexible machine layout to archive measurement of complex parts

- Fast cycle times

- Combination of different sensors, 2-D cameras, 3-D laser measurement

- One-stop solution: project management, engineering, programming and installation

Contact person

Manuel Stix

Head of Business Unit Advanced Technology

manuel.stix@alpinemetaltech.comRequire information DE

DE EN

EN CN

CN RU

RU