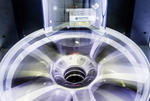

MD30 - Manual distortion measurement

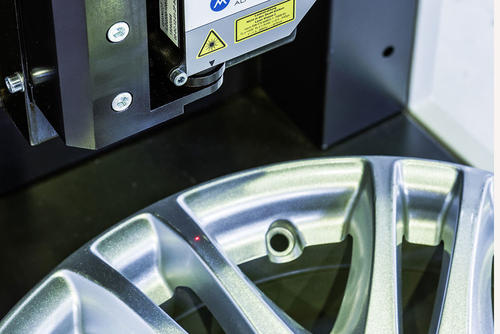

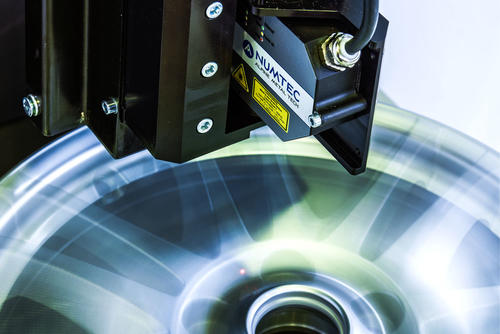

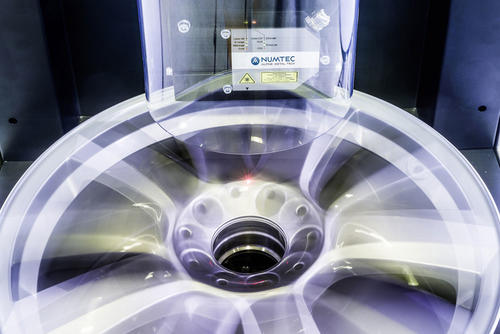

The flexible MD30 laser measuring machine is used for distortion measurement of aluminum wheels during two decisive production steps – in mechanical machining and in the diamond cut process.

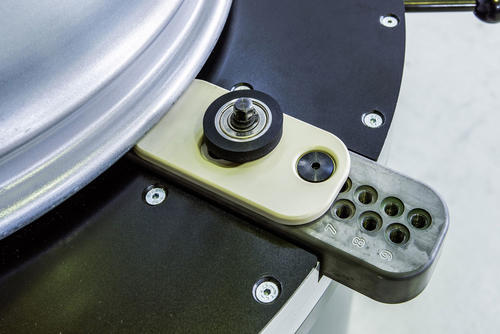

For blank casted wheels in manually loaded CNC machines, the hub distortion and the optimum loading angle in the chucking area are determined for the first CNC operation. The reduced imbalance as well as the improved radial and axial runout properties result in a massive reduction of scrap and rework wheels. A further application of the MD30 is the measurement of finished wheels before the diamond cut process. The painted wheels are measured at the visible flange, at the individual spokes and in the cap area. The correction values determined from this measurement are used for the CNC contour adaptation in the diamond cut process. The resulting gain in the OK rate after the first lathe process causes a significant increase in total system capacity. With the manual height adjustment of the high-precision NUMTEC laser sensor, wheels from 4 to 12 inches in wheel height can be measured. During a measuring process, the operator loads the wheel into the system and centers it in the 3-jaw clamping by means of manual operation. The correction values are then determined fully automatically and can be transferred to the CNC machines manually or via interface. The MD30 is delivered completely assembled and tested and is ready for operation immediately after connecting the power supply. Thanks to its compact design, the distortion measuring machine can be quickly transported to other locations by means of a lift truck. This flexibility and the variable area of application are two of the greatest advantages of the MD30.

Your advantages:

- Flexible area of application: Rapid change of location from mechanical machining (distortion measurement/resting pad determination) to diamond cut area (design measurement) possible.

- No safety equipment necessary: Operation without protective equipment in manual machining lines possible.

- Cost-effectiveness: Massive reduction of scrap and rework wheels as well as low acquisition cost with a concurrent wide range of applications.

- Laser measurement: The laser measurement process guarantees high-precision measurement without wear and without ongoing maintenance costs.

- Data interface: Interface for the transmission of the correction values to downstream CNC machines available as an option.

Contact person

DE

DE EN

EN CN

CN RU

RU