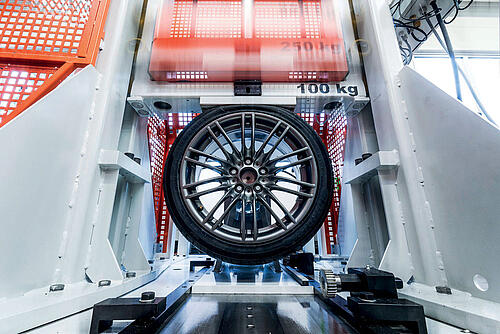

ITB - Impact test

Accident research results require wheels which retain their functionality even under the heaviest of loads. The tests serve to check and simulate the crash behavior of vehicle wheels.

Due to different international requirements, a test facility which tests the impact resistance of the wheel must also be in a position to simulate different loads under identical testing conditions. Once the necessary or prescribed resistance value has been achieved in wheel development, the wheels are subjected to continuous in-process inspection and testing. Different material batches and alloy components make intermediate tests necessary in order to guarantee permanent sustainable manufacturing quality. The MAKRA test bench stands out on account of its simple handling and fast convertibility for a wide range of different test settings. Thanks to the built-in measuring devices, the respective test parameters and test results can be tracked and documented.

The MAKRA impact test bench has been developed for all types of impact tests used worldwide. The scope of delivery includes all drop weights required for various tests (see Technical Data). The weights are individually loaded into the machine by the chain hoist. The drop height can be preselected using a digital scale and the required impact angles are easily adjustable.

In order to obtain even more precise data, the MAKRA impact test bench optionally offers the monitoring of the fall/impact speed in m/s or km/h.

The test procedure is trigged by an electro-pneumatic two-hand release. To guarantee the highest level of safety for the operating staff, the test procedure will not start before the mechanical fall protection has been manually unlocked. Due to the adjustable roller guide of the fall cart a smooth guidance is guaranteed.

Your advantages:

- Certified test machine manufacturer: MAKRA measuring machines are approved and certified directly in-house by well-known German vehicle manufacturers (BMW, AUDI, Daimler, Volkswagen, Porsche etc.).

- Robust machine frame: A torsion-resistant and sturdy machine frame guarantees reliable test results.

- Different wheel clamping systems: Only one wheel chuck is needed for all common wheel sizes and types of attachment.

- Comprehensive area of application: Different impact angles, impact plates/wedges and drop-weight versions can easily be adjusted. All common impact and radial run-out tests to be carried out on the test bench.

- Protective equipment: Multiple fall protection devices and safety doors garantee the safety of the operating staff.

Contact person

DE

DE EN

EN CN

CN RU

RU