HS Hot Spray Marker

The Hot Spray marking machine is one of the earliest developments of Alpine Metal Tech and the most popular technology to mark hot products.

The cost-effectiveness and simplicity of the marking technology are the main reasons for the long-lasting success of this technology. Marking is performed by blowing liquid metal which is melt in an electric arc between two wires to the surface of the product.

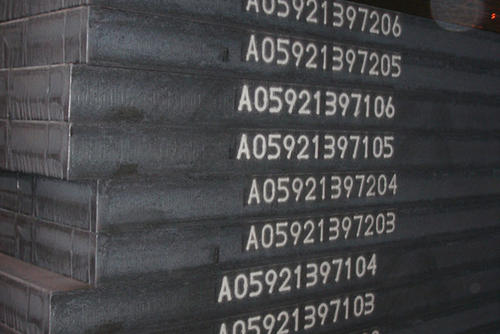

The marking unit case as housing and heat protection for the marking system is mounted either on a multi-axis machine or on a robot. In addition to the marking system, the marking housing contains a descaling unit to remove loose scale from the marking surface. The descaling unit is also used to detect the product. The principle of this marking process is originated on thermal metal coating. Two wires are fed through a spray gun and are continuously melted by means of electric current forming an arc. The two wires are fed from two spools placed in the marking unit. The spray wires are transported via the feed rollers through the wire nozzles to the point of short circuit in the nozzle system. The writing movement is then carried out and the marking wire is melting to the material to generating clearly visible characters.

Your advantages:

Low production costs due to use of standard aluminium or bronze welding wires.

Large characters offer a high visibility even for crane operators.

Long-lasting marking and therefore high traceability

Easy to maintain and therefore a perfect technology for harsh environments where a durable and reliable marking is required.

Contact person

Markus Sternbauer

Head of Business Unit Steel

markus.sternbauer@alpinemetaltech.comRequire information DE

DE EN

EN CN

CN RU

RU