DP Dot Paint Marker

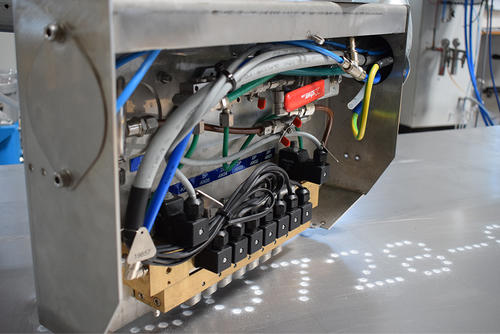

The Dot Paint Marking Machine is designed for the marking of slabs, blooms and billets at continuous casting platforms.

The Dot Paint marking machine is one of the earliest paint marking developments that has undergone numerous advancements over the years. This advanced technology is capable of marking on products, even at very high surface temperatures, and at high product moving speeds.

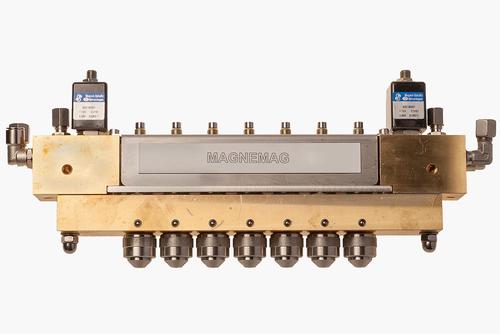

The marking section is available in two different sizes equipped with 7 or 9 paint nozzles. The equipment is specialized for product markings with a request for low cycle times. The marking can be applied up to 1,5m/s during conveyance and provide a marking content of standard and special characters, logos, 2D codes and cut markings.

The marking nozzles mounted in the sections provide paint dots with an adjustable diameter of 8-12 mm.

One of the latest developments is the integration of Alpine Metal Tech’s new marking control unit MCU200 which delivers a complete electric redesign of the control unit and its output cards to increase marking functionality. New communication interfaces and automated cleaning and by-pass functionalities to reduce and simplify maintenance requirements.

The development of Alpine Metal Tech’s various paint and solvent types and their supply units completes the marking machine to fit to the environmental and process operational requirements.

Your advantages:

The high marking speed enables markings with up to 1,5m/s even during conveyance of the product without stops

Fully automated paint circulation and cleaning sequences reduce maintenance requirements.

Useable with a variety of Alpine Metal Tech paint and solvent types for a range of temperatures up to 1000°C and customized to needs.

Add on:

Contact person

Markus Sternbauer

Head of Business Unit Steel

markus.sternbauer@alpinemetaltech.comRequire information DE

DE EN

EN CN

CN RU

RU