CJ CombiJet Paint Marker

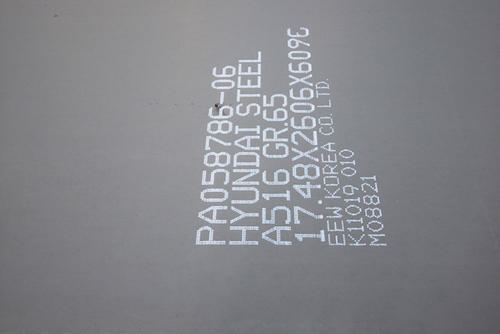

The CombiJet Paint Marking was developed to apply clearly visible dot paint markings in high resolution. The machine technology is available in different designs to mark various product shapes and temperatures up to 400°C in harsh industrial environments.

The advanced CombiJet technology enables markings for limited space which are readable by automatic identification systems (Data Matrix codes). Also large-area markings in form of corporate logos, 2D codes, cut marks, plain text in different character sizes and styles or customized combination can be realized.

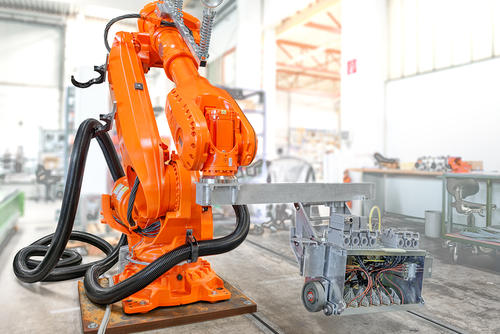

The CombiJet Marking is available as robot type, to be flexible to individual coil sizes and to fit individual requirements.

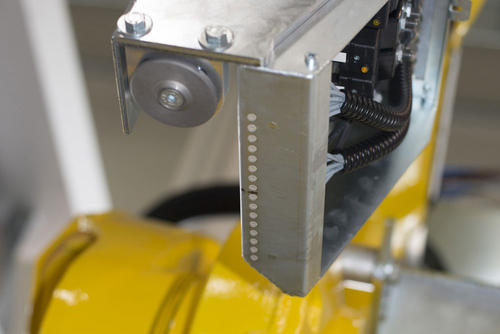

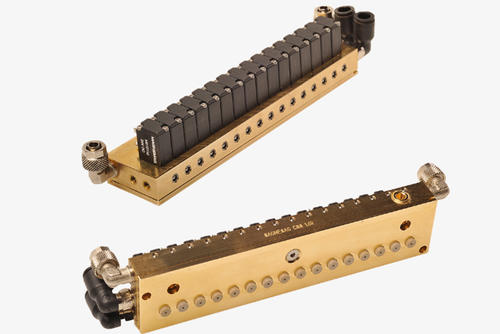

The CombiJet technology is based on an intelligent combination of marking sections with several paint nozzles and a marking control unit. The control unit MCU200 like the CombiJet marking sections, is a proven development of Alpine Metal Tech. The interaction between the control unit and marking section provide an excellent marking quality during standstill as well as at high speed conveyance of the product. Furthermore, low maintenance needs and low running costs due to automated cleaning cycles and improvements on air and paint consumption is given.

An intelligent linking of several marking sections via one controller facilitates gapless marking images throughout all CombiJet nozzles. This allows various marking lines in different character sizes and styles (e.g. bold, italic, upside down) together with special characters (e.g. Chinese, Cyrillic, Japanese, Farsi, certification marks,...). corporate logos, 2D codes and cut markings in one area.

A selection of paint and solvent types as also the paint supply units developed for different requirements completes a smooth running machine for your demand.

Your advantages:

- Low running costs

- Reduced cycle time

- Higher resolution, lower drying times and less over spray compared to conventional marking technology

- Fully automated by-pass and cleaning sequences reduce maintenance requirements. Plug and play solution for marking section replacement without any nozzle adjustments

Contact person

Markus Sternbauer

Head of Business Unit Steel

markus.sternbauer@alpinemetaltech.comRequire information DE

DE EN

EN CN

CN RU

RU