Successful launch of new KNORR rail brushing machine

09.05.2019

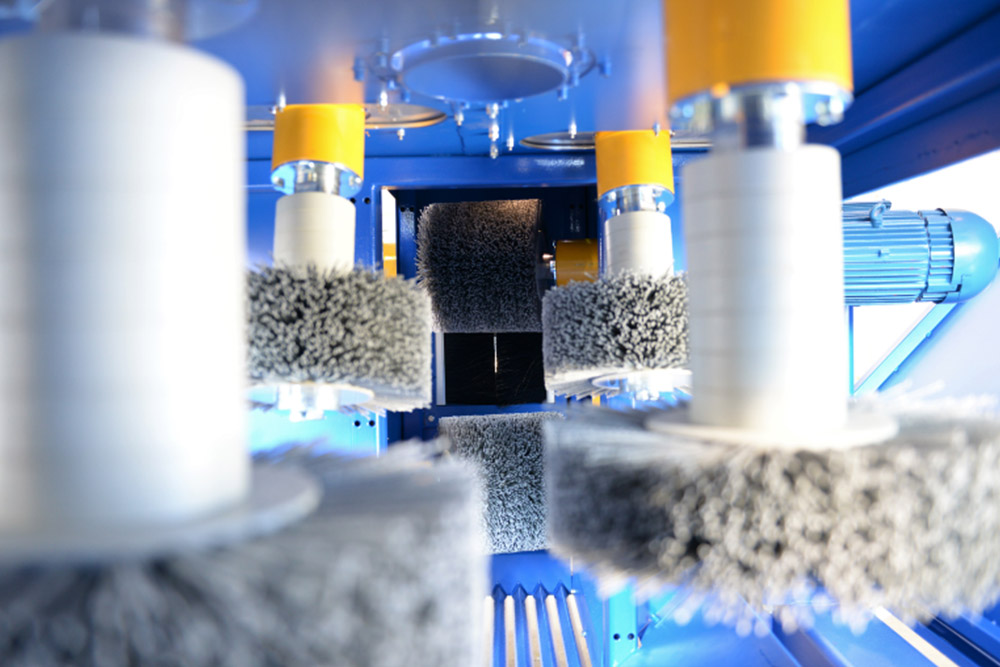

The new features are:

- Consistently high brushing performance due to force-controlled guiding units

- Easy change-over between rail profiles

- Brush wear monitoring

- One brush dimension fits all brushing units

- Modular design reduces inventory of required spares

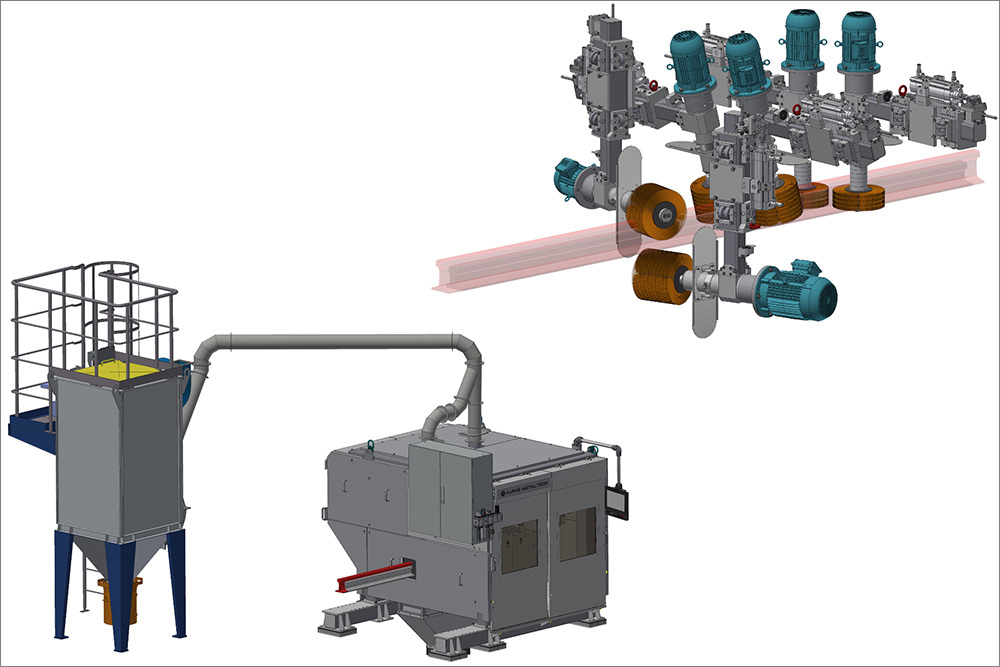

Brushing is the most convenient and economic way for pre-conditioning of rail profiles prior to non-destructive testing. KNORR’s brand new brushing machine improves the reproducibility of the entire testing process by significantly reducing the amount of loose and adhering contaminants, such as scale.

Coarse dirt is collected in a removable bin underneath the machine whereas dust is safely disposed of by an automatic filter system.

Less contamination of the downstream testing machines is the consequence, which in turn also leads to a higher overall availability of the entire testing line and lower cleaning effort.

If you are interested in our products, please don´t hesitate to contact us directly:

Alpine Metal Tech GmbH

Buchbergstraße 11

4844 Regau, Austria

Tel. +43 7672 78134-0

E-Mail office[at]alpinemetaltech.com

DE

DE EN

EN CN

CN RU

RU