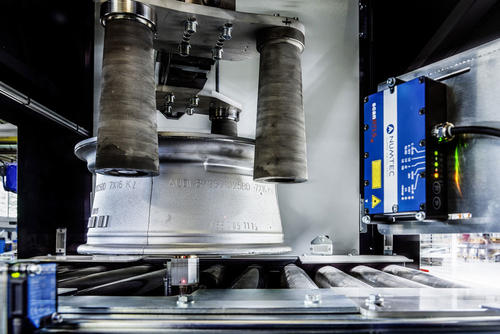

MARK100 - Marking system for aluminum wheels

The MARK100 marking machine is an all-in-one system for the automatic embossing of characters on the inside of aluminum wheel blanks. A wide range of different inspection stamps (day, shift, hour, x-ray stamp, etc.) can be applied fully automatically at predefined positions.

The system has been designed as a throughput version with closed housing. As a result, the need for an additional loading and unloading process (e.g. robots) is eliminated. All the necessary machine parts, including control cabinet, are integrated in the housing. This allows for the machine to be completely assembled and tested during installation and final inspection at Alpine Metal Tech. There is no longer any need to dismantle the completed machine for transport, which in turn shortens the commissioning time on the premises of the end customer. The MX01 embossing head developed by Alpine Metal Tech is used as the marking system. Due to its pneumatic drive, the MX01 offers more flexibility in terms of impact energy and marking distance (due to distortion on the wheel) in comparison with conventional electro-mechanical marking systems. The fed-in wheels are centered and lifted from the roller conveyor. By moving the in the gripper unit integrated rotating system the NUMTEC barcode can be read for type identification and the determination of the position. After type identification, the marking head is positioned from below into the wheel, and the marking process is carried out at the predefined position. Thanks to the slim design of the marking head, reliable marking up to a distance of approx. 30 mm from the drop center or into deep pockets is possible. With the use of the NUMTEC barcode system, the wheels can be fed completely chaotically and for each wheel a separate, independent marking position can be predefined.

Your advantages:

- Short cycle times: Fully automatic marking of up to 220 wheels per hour

- Reliable marking: Captive marking through NUMTEC MX01 technology; remains visible even after coating and painting

- Maximum availability: Reliable marking through automatic function control of the entire marking unit

- All-in-one system: Marking system is delivered to the customer as a prewired and tested unit

- NUMTEC barcode system: Type identification with the NUMTEC barcode system

Contact person

DE

DE EN

EN CN

CN RU

RU