PP/EP - Punch Marking

The punch marking machines were developed for products which need to have reliable permanent markings. The adjustable punch force of these machine type allows to punch plates with different steel grades in consistent penetration depth. The punch marking can even mark hot products with up to 1100°C.

Pneumatic Punch Single Needle

A single needle marking head is designed for markings at positions with little space.

The PP Pneumatic Punch Marking is used to mark uneven surfaces which require a multi-directional movement of the punch needle during the marking process. The single punch marking head is manipulated by a robot wrist to realize the character writing movement.

Pneumatic Punch Needle Section

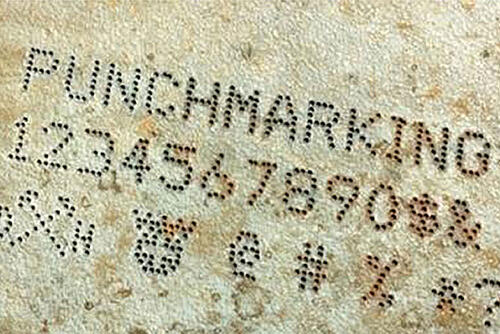

The needle section for the Pneumatic Punch Marking is available with 9, 23 or 32 needles. A marking image with up to 3 lines and gapless logos, 2D codes or special signs in height with up to 32 dots can be realized. The whole marking image is carried out during one linear stroke only. This decreases cycle times even further.

As the exhaust air of the marking head is used for internal cooling of the marking head, an additional cooling is not required. Not even for markings on hot products up to 1100° C.

Electric Punch Marking

In difference to the pneumatic puncher the control is done by electromagnetic force which activates the high power stroke of the punch pins.

The marking head is available with up to three punch sections which can be equipped with 3-9 pins each row. The marking sections move in X and Y direction within a fixed marking window, where every single pin can care for a marking field of 3.5 characters. During one marking cycle a maximum of 30 characters in up to three lines can be applied.

During marking, electrical signals are sent to the punchers of the marking head, the high timing accuracy and the high penetration force ensures consistent high quality marking. An internal cooling air arrangement takes care to prevent an overheating of the punch coils.

您的优势:

Low running costs - Punch pins can be multiply resharpened by maintenance staff

High resolution with up to 4 lines during one linear movement

Permanent marking even for steel grades with higher levels

Punch pins can be easily exchanged during short stops

联系人

DE

DE EN

EN CN

CN RU

RU