First motor block deburring cell RDM100

16.11.2023

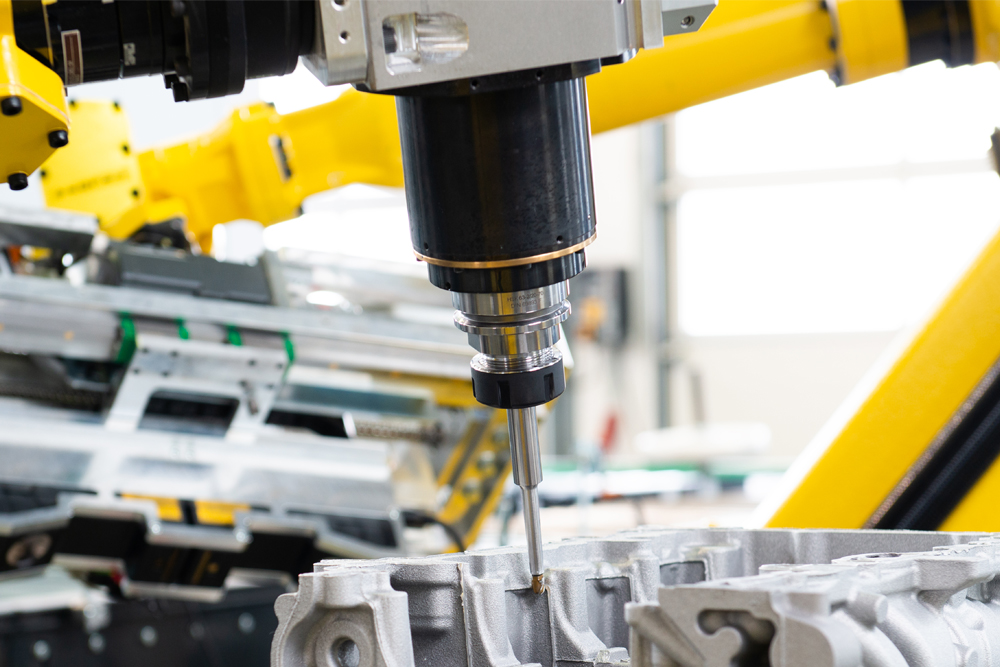

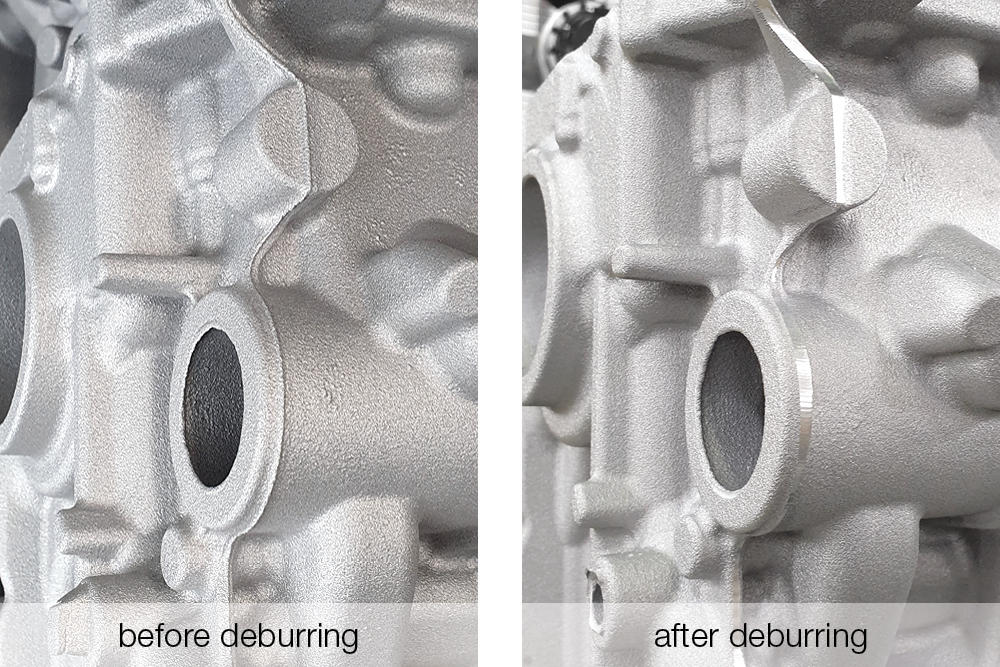

Casted aluminum parts, especially for the automotive industry, require high surface quality. Machining flashes, casting burrs, or sharp edges are not acceptable at many applications. Deburring and the teach-in process are currently carried out manually. As a result, every part looks different. The flexible robot deburring system ADoC (Automated Deburring of Castings) removes flashes and burrs on casted parts fully automatically and meets the highest standards of product quality and repeatability. This boosts production capacity to a maximum and reduces manual rework to a minimum. The ADoC system is applicable in deburring of any kind of castings, such as battery housings, motor blocks and chassis parts for cars and motorcycles as well as aluminum wheels.

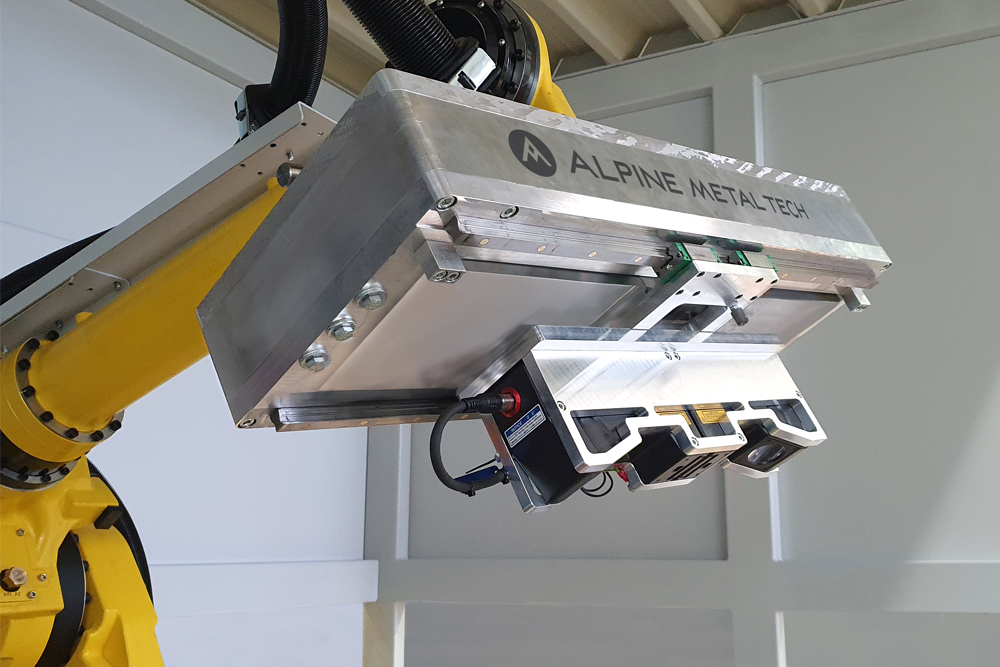

Alpine Metal Tech built the first fully automatic motor block deburring cell RDM100. Achieving the required deburring tolerance at a high machining speed has been a huge challenge to the Alpine Metal Tech team. By using in-house laser measuring know-how, paired with latest state-of-technology sensors and intuitive offline teach-in strategies, the requirements have been fulfilled.

The development of the sophisticated machine took more than two years and thanks to a successful collaborative approach, the first RDM100 was delivered in time in August. The new ADoC system increases the customer’s production capacity and enables new quality standards.

The RDM 100 video and ADoC product folder can be found HERE.

DE

DE EN

EN CN

CN RU

RU